Jaker Chen

Jaker Chen  April 09,2022

April 09,2022

How to achieve color management?

In the process of copying color images, to achieve color uniformity from scanning, display, output to printing, it is necessary to implement standardized, standardized and data-based color management. The so-called standardization refers to the production of products using standard raw materials and equipment in the standard state of production and standard data in the production process. Standardization refers to the production process and standard construction according to a certain procedure. Quantitative indicators, everything can be expressed with data values, the three complement each other, and the whole is scientifically combined to achieve the purpose of stabilizing and improving product quality during mass production.

Color management includes: 1. Color matching between input devices. 2. Match between the color of the original and the color of the display. 3. Color matching between output devices. 4. Match between the color of the display and the color of the printed matter. 5. Color matching between the original and the printed matter. Color management is to solve the problem of color conversion and matching between various devices. First, establish a standard light source for a standard color environment, and the core components of the standard light source should have a higher color temperature and a higher color rendering index. 6500K, the color rendering index is usually> 95%. 5000K is a CPM (mini) transmission standard light source; the color rendering index of the German JUST fluorescent lamp is 97%. The standard light source is used to observe the proof sheet while requiring constant indoor light.

Second, choose a color space (CIE, LAB) independent of the device. According to color theory, any white light color can be matched by the three source colors R, G, and B, but the ratio of the three primary colors is not unique; any neutral Gray can be matched with the three source colors C, M and Y of the color material. However, due to the incomplete absorption of light by the colorant, black ink must be used to make up the ideal neutral gray and satisfy the actual printing effect. In this way, the same color block is expressed by different equipment, and the ratios of C, M, Y, and K are different. For example, when a color block is printed and reproduced with Tianjin ink, the proportion of CMYK is 64%, 36%, 8%, and 10%, and when reproduced with an inkjet printer, the proportion is 60%, 30%, 10%, and 10%. The physical quantity CMYK describing the same color is related to equipment and materials. If CIE Lab is used to read the above color patches, the CIE Lab value (70, 40, -12) during printing and the CIE Lab value (70, 40) during inkjet proofing should be guaranteed. , -12) The same, then the appearance of the color is visually consistent, which shows that CIE Lab is independent of the device and describes the physical quantity of the color independently. The color gamut of the CIE Lab color space is much larger than any other device-related color space, so that the color gamut range will not be lost in the reference color space during the color conversion mapping process. Color management is to use independent CIE Lab, a device-independent physical quantity, to communicate and calculate the correspondence between the original color, the screen color and the printing color in the color space, to achieve the visual consistency of the colors, and realize the conversion of different devices and colors. Color conversion refers to the conversion of colors in different color spaces. The Lab color space can be used as a transitional color space, which can complete the conversion between various device colors, and can also convert the infinite combination conversion relationship between the device and the device into the device space and the standard color space. The five-to-five correspondence relationship greatly simplifies the complexity of matching conversion.

Then, create a profile describing the color of the device to reflect the range and characteristics of the device's color, and use this profile to complete the mapping between the color space of the device and the Lab chromaticity space. Color management uses the following process structure to complete the uniformity of cross-platform and system transfer of color conversion.

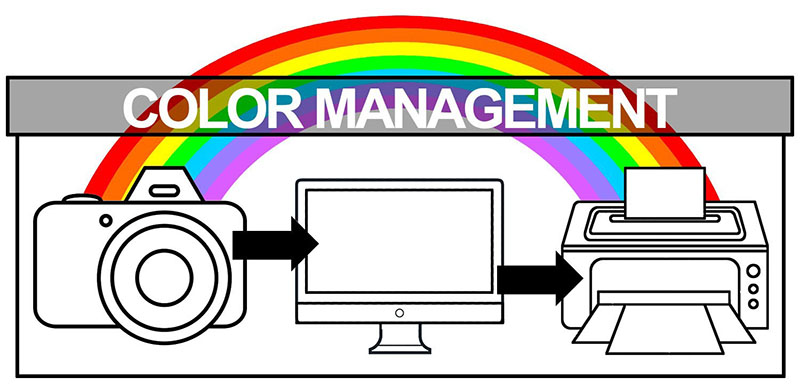

As can be seen from the above process structure diagram, a core color conversion engine (Lab) converts the RGB information input by various device feature files, that is, the RGB information of the scanner, the RGB information of the display, and the CMYK information output by the printing device . The collection of various information data is the basic work of color conversion. If it is not done well, other conversion work will be wrong. Therefore, equipment standards must be established for equipment calibration. Use the calibration process to generate a new color profile that matches the current work. In the color management system, the fundamental purpose of calibration is to make the actual working state of the device consistent with the state described in the device characteristic file.

Implementation of standardized color feature file format, the current ICC format has become such as Apple's Color Syne; Windows98 ICM (Image Color Mathing) system common standards define color image TIFF, PIC and EPS file formats; the combined feature file information can be embedded in image files In order to completely solve the inconsistency of color transmission and maintain the accuracy of color.

The following describes the method of generating characteristic files of color displays, scanners, color inkjets, laser printers, and color printers.

The color display is in between the input and output in the entire color processing process. Therefore, whether it can accurately display the input manuscript or accurately predict the color effect of the output result will directly affect the WYSIWYG performance of the entire management system. Under standard light sources, use screen chromaticity to measure, correct the screen, and use the supporting software to generate a device characteristic file for the current working state.

A scanner is a device that reads colors, and the methods for generating scanner signature files are similar. First scan a standard color scale, the current commonly used IT8 color scale, the color scale is composed of 264 color blocks, representing the entire CIE Lab color sampling, with a 23-pole neutral gray scale at the bottom. Now the companies that produce color scales (Kodak, Fuji, and Agfa) will have microwave differences between the various color scales they produce, but these differences can be analyzed without affecting the accuracy of the color management system using color scales. The color patch on the color scale measures its color value Lab by the calibrated spectrophotometer, thereby generating the Lab parameter table of the color scale. This parameter table is generally attached when the manufacturer provides the color code. When you want to create a characteristic file of a scanner, use the scanner to scan the color code and obtain the RGB value of each color block on the color code. In this way, you can create a quick reference table for the conversion between RGB and Lab. It can be used to map a certain point of the RGB file generated on the scanner to the Lab space. This is the basic structure and usage principle of the scanner characteristic file. Scanners will have parameter drift with the length of time. The limitations of the scanner device profile that change with conditions bring discreteness to color management. Therefore, the scanner must be calibrated. The professional scanners produced now take the scanners of Tango and Putian systems in Heidelberg as an example. The scanning software used by New Color 7000 has already been equipped with strong color management features. Customers worry about ensuring the accuracy of the scan. ICC feature files with standard display RGB can also be added to the customer's RGB feature files for the current working state. It uses RGB direct files for scanning to generate Lab image patterns, which can be modified at will Image feature files, saturation, brightness, hue, without rescanning, has great flexibility, can embed various device feature files into color images.

With the popularity of spectrophotometers, the characteristic files of color inkjet, laser printers and printing machines all use the color mark generation method. The digital color mark of IT87 / 3 has a total of 928 colors composed of different CMYK combined values. Block, respectively print out CMYK digital color mark on color inkjet, laser printer output and according to the paper and ink currently used by them. Then, use a spectrophotometer to measure the Lab chromaticity value of the printed sample and each color block of the printed product, fill the record table and save it, establish the mapping conversion relationship between the CMYK color space and the Lab color space, and generate specific color printing. The signature file of the process.

To effectively manage the color between systems and applications, it is very important to embed the ICC feature file in the file. The ICC feature file will indicate the correct color space of the file. When another cognitive ICC application opens an image, The application can know whether to perform color conversion and conversion accuracy. For example, color management is applied in digital proofing. The purpose and function of proofing is to check the pre-press color separation effect and the accuracy of editing and layout, to provide customers with signature prints for printing. Digital proofing does not require carriers (such as film and PS version) to transmit graphic information; Carrier graphic data information transmission, so digital proofing is also known as proofing method without software and without printing plate. There are two main types of digital proofing equipment: color inkjet printers or color laser printers. Digital proofing can realize the samples that simulate traditional proofing, and provide standards and basis for printing. Finally, there are environmental standards, color conversion standards, and equipment standards; with a color feature file describing the equipment, color uniformity is achieved through color management software, and WYSIWYG is achieved in color management.

Throughout the process of making color images, from no data, to the establishment of data, the proposed standards to the stability of data, so that color management under the open structure becomes possible.